What ist the Formwork Shoring Scaffolding?

Formwork scaffolds are temporary structures used for placing molds of elements such as slabs, beams and columns in reinforced concrete structures and for pouring concrete. Formwork scaffoldings are designed according to TS EN 12812-1, TS EN 12812-2, TS EN 12813-1 and TS EN 12813-2 standards. These standards determine the strength, durability and safety requirements of formwork scaffolds.

Formwork scaffolds can be of different types. The most common formwork scaffolds are:

Table Type (H Type) formwork scaffolding: Table scaffolding type formwork scaffolds are formwork scaffolds formed by connecting H type (Frame Type) vertical elements to each other with horizontal and diagonal elements.

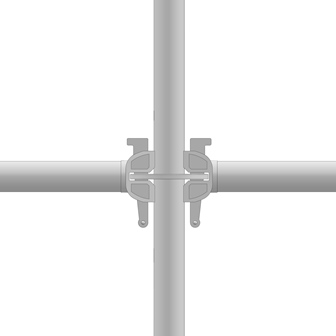

Ring Lock formwork scaffolding: This type of formwork scaffolding is formed by connecting horizontal elements and diagonals to each other with the flange and dovetail locking system of the uprights.

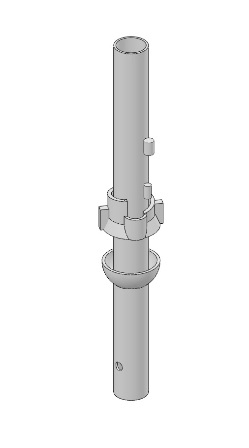

Cuplock formwork scaffolding: This type of formwork scaffolding is formed by connecting the horizontal elements to each other with the cup lock system of the uprights.

Tower Formwork Scaffolding: This type of formwork scaffolding consists of mounting sleeve frame elements to each other.

Telescopic Props: This type of formwork scaffolding is formwork scaffolding that can be adjusted in height thanks to the telescopic structure of the props.

Formwork scaffolds may have different features depending on their intended use. For example, formwork scaffolds used for floor formwork must have different properties than formwork scaffolds used for beam formwork. Installation and dismantling of formwork scaffolding should be done by experts. In order for formwork scaffolds to be used safely, they should be checked periodically.

Formwork scaffolds designed according to TS EN 12812-1, TS EN 12812-2, TS EN 12813-1 and TS EN 12813-2 standards have the following features:

Durability: Formwork scaffolding must be strong enough to carry the weight of elements such as floors, beams and columns.

Durability: Formwork scaffolding must be resistant to external weather conditions and impacts.

Safety: Formwork scaffolds should be designed to ensure the safety of employees.

Formwork scaffolds designed according to these standards allow the safe use of employees and materials.

The main duties of formwork scaffolds are:

- Ensuring the placement of molds for reinforced concrete elements

- Ensuring the stability of molds during concrete pouring

- Ensuring that the molds are smooth during concrete pouring

- Ensuring the safety of employees during concrete pouring

Formwork scaffolds have an important role in construction projects. Safe use of formwork scaffolding directly affects the quality and durability of reinforced concrete elements.

As Yapeksan Scaffolding, we have five different models that we produce to provide safe formwork scaffolding.

- Masamod® H Type | Formwork Shoring Scaffolding

- Flamod® Ring Lock | Formwork Shoring Scaffolding

- Kulemod® Tower | Formwork Shoring Scaffolding

- Finmod® Cup Lock | Formwork Shoring Scaffolding

- Telmod® Props | Formwork Shoring Scaffolding

1. Masamod® H Type | Formwork Shoring Scaffolding

It is a scaffolding model designed and certified according to TS EN 12812 and TS EN 12813 standards and used as carrier scaffolding under floors and beams. Masamod scaffolding system is a heavily loaded formwork scaffolding that is generally used as formwork support in structures where the distance between floors and floor concrete thickness are high. Masamod scaffolding system has a very rigid structure with its frame system and horizontal and diagonal elements.

2. Flamod® Ring Lock | Formwork Shoring Scaffolding

It is a scaffolding model designed and certified according to TS EN 12812 and TS EN 12813 standards and used as carrier scaffolding under floors and beams. Flanged formwork scaffolding system is formed by connecting horizontal elements and diagonals to each other with the flange and dovetail lock system of the uprights.

3.Kulemod® Tower | Formwork Shoring Scaffolding

It is a scaffolding model designed and certified according to TS EN 12812 and TS EN 12813 standards and used as carrier scaffolding under floors and beams. Kulemod® Tower Scaffolding system is generally used as under-formwork support in structures with high storey heights and large slab thickness. The Tower scaffolding system has a very practical installation and rigid structure with only 4 parts.

It is a scaffolding model designed and certified according to TS EN 12812 and TS EN 12813 standards and used as carrier scaffolding under floors and beams. Cuplock type formwork scaffolding is formed by connecting the horizontal elements to each other with the cup lock system of the uprights.

5.Telmod® Props | Formwork Shoring Scaffolding

Telescopic props adjustable formwork scaffolding system is designed and produced in accordance with TS EN 1065 standards.

It is a formwork scaffolding system that is used as a carrier under the slab, is practical to install, can be easily carried by hand and is lightweight. It can be easily applied on the floors of all kinds of different architectural structures. Thanks to its design and lightness, it offers economical solutions in projects due to the low cost of the product.

The telescopic props adjustable mounting system consists of three main elements. Telescopic props are the main element of the system. Auxiliary elements of the system; tripod support stand, U-Head element, T-Head element and Four-Way Head.

+90 212 423 3378

+90 212 423 3378